Designing smart solutions for MESCH with Ultima Forma

Blog

Ultima Forma is one of the key partners for the MESCH project, bringing their engineering expertise to hydrogen storage. In this interview, Steve Newbury, Managing Director from Ultima Forma, shares insights into their technical approach, collaboration with partners, and experiences from the project.

To begin, could you tell us about Ultima Forma’s involvement in MESCH and the focus of your work?

Ultima Forma is developing a large, low-cost hydrogen storage system for the MESCH project, designed to be installed at the demonstration facility in Malawi. Our activities are focused mainly on the first half of the project, after which we’ll help oversee the installation of the hydrogen storage system.

What made MESCH a project Ultima Forma wanted to be part of?

We’ve been involved in a number of hydrogen storage projects and hold patented technology for electrodeposited hydrogen barriers. MESCH is exciting because it uses renewable energy to produce both electricity and hydrogen gas. The concept of large-volume, low-cost hydrogen storage has wider relevance, and storing hydrogen at lower pressures than conventional pressure vessels offers a new economic model.

Technology in focus

What kind of technology are you developing for MESCH, and how does it support the project’s goals?

We’re developing the storage system through CAE modelling and CAD design, creating a system that can be purged with water to prevent air from mixing with hydrogen. The storage pipe is connected to a system that transfers hydrogen to and from the above-ground infrastructure. One of the project’s key goals is to enable cooking using stored hydrogen from the electrolyser. This is our main deliverable.

MESCH is a collaborative project with partners from different sectors and countries. What’s been your experience working together so far?

The MESCH team worked well together on the individual parts of the project. This is now being brought together in the first system, which is ready for certification and shipment to Malawi. Everyone is actively working towards delivery this summer.

How do you see MESCH making a difference in communities where energy access is still limited?

Further economic mapping of this technology versus solar plus storage will be needed. As we gain more insight into real costs through this project and with changing costs in solar and battery storage, we’ll be able to compare like-for-like costs, including infrastructure and end-of-life considerations.

Progress through collaboration

What’s been one of the most rewarding parts of working on this project so far?

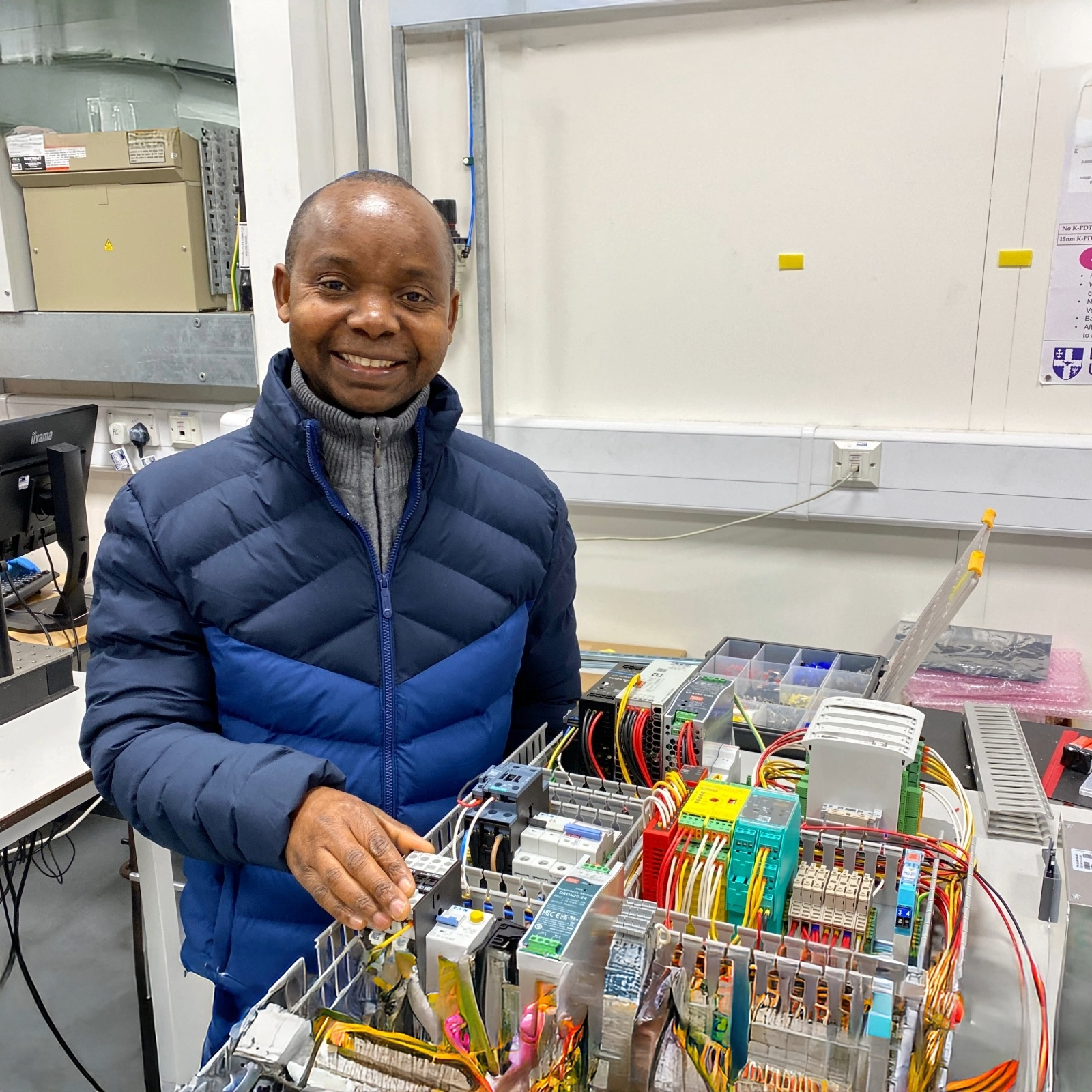

We’ve been working closely with the Loughborough team on the technology development, and it’s been a pleasure getting to know them and seeing the exciting progress that’s been made so far.

Has working on MESCH influenced how you think about energy, innovation, or engineering in any way?

The idea of using existing materials and modifying them for new applications is something we can all learn from. For example, modifying low-cost pipes could significantly help reduce hydrogen storage costs depending on the use case. Our modelling has calculated leakage rates for polymers, so even non-ideal materials can still play a valuable role depending on the storage cycles involved.

What makes a project like MESCH valuable from an innovation and industry perspective?

It brings new partners together. It enables projects to be trialled in a non-Western environment, where the cost base differs. Building a showcase facility with a strong social purpose also provides a platform for positive awareness and marketing of the demonstrated technologies.